IMG - Injection Molding Guide

#SamplingNXTGeneration!

Digital Transformation…

The smart software for tool sampling and series processes.

Standardization

Digitization

Networking

Process safety

Training campaign

Distributor:

References

The InjectionMoldingGuide is in successfull use at…

Simplify your data exchange nationally or worldwide…!

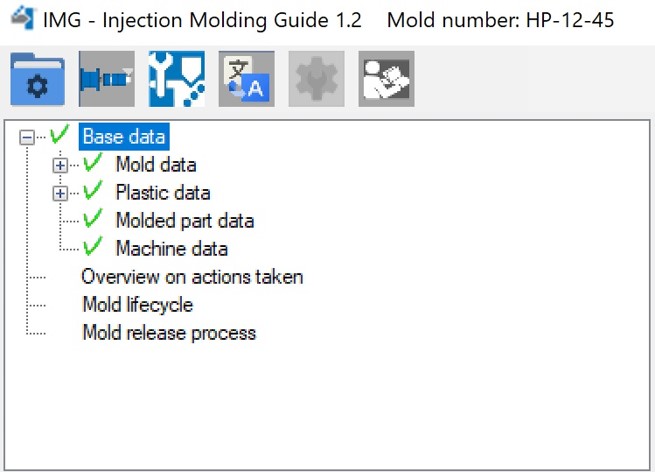

With the help of master data, time resources can be saved in advance.

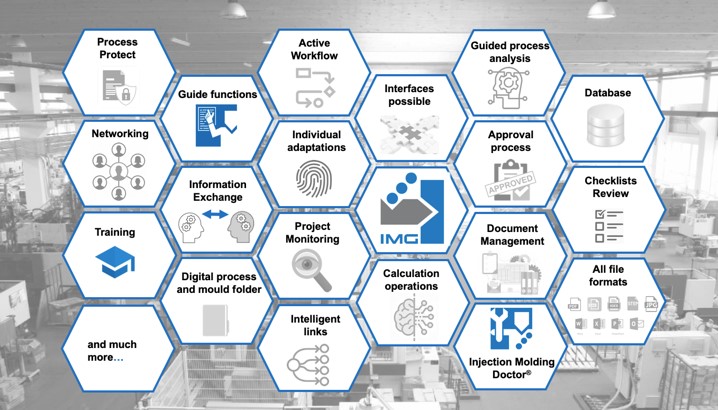

The IMG offers the following advantages:

-

Data can be stored quickly and easily and serve as information and data transfer to the individual departments throughout the entire sampling process.

-

With the help of the internal database, all data created, such as the plastic to be processed or the injection moulding machine used, can be stored.

-

Documents, templates, images and photos can be integrated and edited.

-

Numerous links from the master data contribute later in the software to a more effective time-reducing processing of the individual steps.

Standardize & digitize your process nationally or worldwide…!

Operational implementation

with the IMG

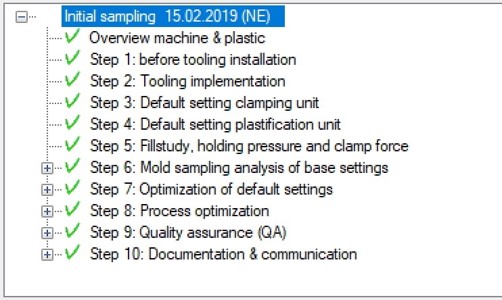

Once all the important background information has been compiled, inserted and saved under master data, the next step is the operational part on the machine.

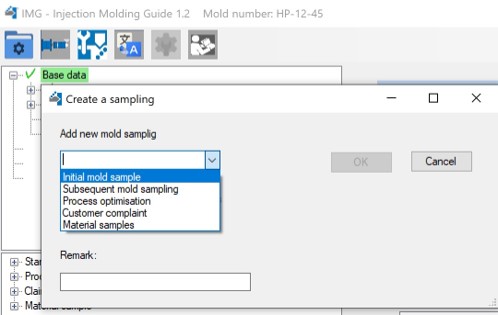

The user can choose from the following options under the button "Add new sample" (Fig. 1). Choose categories like:

- Initial sampling

- Follow-up sampling

- Process optimization

- Material samples

- Complaint

Figure 1: Add new sample

Figure 2: IMG structure tree

Network with the IMG internally, nationally or worldwide…!

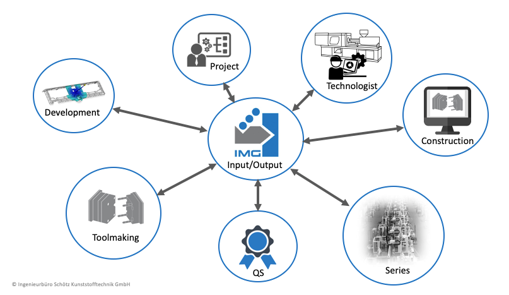

Many companies have other plants nationally or globally around the world in addition to their headquarters.

Use the IMG software to live your standardized process nationally or globally, to set up injection molding processes together, to examine them or to support them in case of problems.

Use the IMG internationally…

English language package

included

The IMG is completely switchable to English language…

Coming soon!

More language packs are planned!

IMG-Training campaign national or worldwide

Promoting education and training via integrated help tools…

If the user requires more background information during the ongoing sampling or process optimization, e.g. for the setting strategy of the basic setting of machine setting and process parameters, the integrated guide with numerous instructions, graphics, tables, photos/images leads specifically through all sampling or optimization steps on the machine.

Every employee can carry out a systematic and structured error detection up to the definition of measures and optimization strategies in three quick and effective steps on site at the machine.

IMG-Processprotect

Problem in practice…

-

Is your currently validated process from the sampling also used 100% in series production?

-

Are there often several machine settings for the same tool?

-

Are those responsible automatically notified in a timely manner in the event of process changes in the series?

-

Are all incidents or changes to machine and process parameters properly documented?

-

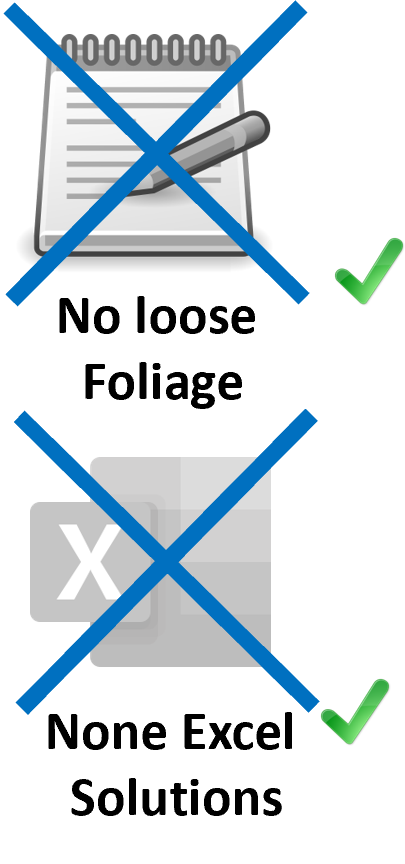

Do you still have process folders in Excel or paper form on the machine?

-

Are there often partly outdated process documents on the machine?

-

Are the documents on the current process or tool often incomplete?

With IMG Processprotect you have all the these problems are solved immediately in the company…

Intelligent IMG functions & release process

Automatic update for series documents

Digital process and tool folder

Digital process history

Storage of the machine data records

Interface possible to internal BDE/MDE systems

Benefit through IMG…

Standardized workflow ready and operational…

-

Problem, time and cost reduction of the entire process

Reduction of throughput times to series production

Saving effort and resources

faster execution of a single tool sampling

-

Improvement of communication and documentation among the departments

-

Improve the productivity, cost-effectiveness and energy efficiency of any injection molding process

- Clear, transparent and structured process internally, nationally & globally

Digitized & networked process

-

Faster information exchange and data transfer possible before, during and after tool sampling

-

Parallel work of all departments involved in the project before, during and after tool sampling saves resources, time and money.

-

Intelligent document management

-

Carry out the sampling process at external suppliers on a mobile basis using a tablet or laptop.

(e.g. the first tool start-up at the tool shop in China)

-

No data islands of individual departments

Test free of charge and without obligation…!

How? Simple…

Step 1: Contact us…

Step 2: Kick-off

- When would you like to test?

- How many test licenses do you need to represent an optimal workflow in the company?

- Who is your responsible IT employee (contact person)?

Step 3: Contact your IT department

- Contact details of the IT employee

- Our IT department will exchange information with your IT department and clarify all details.

- Date coordination (start of the test phase)

Step 4: Installing the test licenses

- Our IT supports you in this

- Activation of the test licenses from the start of the test phase (30 days, optionally extendable)

Step 5: Start of the test phase

- Technical support via TelCo, WebEX or TeamViewer during the test phase as required

Our innovation & idea needs strong partners…

IT partner for

Maintenance & Service

MAIT Germany GmbH

Gutenstetter Str. 10

90449 Nürnberg

Web: www.mait.de

Tel.: +49 (0) 911 642597 24

Support: +49 (0) 234-9594-121

support@mait.de

Partner for IMG Trainings / Knowlegde Transfer

Digital Sampling Department

Engel Deutschland GmbH

Donaustraße 83

90451 Nürnberg

Web: www.engelglobal.com/de

Tel.: +49 911 64 17 20

Hotline: +49 911 64 17 2 38

training.nuernberg@engel.at

SKZ - KFE gGmbH

Friedrich-Bergius-Ring 22

97076 Würzburg

Web: www.skz.de

Hotline: +49 931 4104-0

kfe@skz.de